Don’t buy a 3D printer. You won’t see me write that often, but right now there is a good reason: there’s a new South African-designed 3D printer in town, which will be going on sale within the next few weeks. And if all goes according to plan, says its creator, it’ll be bigger, stronger and cheaper than existing 3D printer designs – and it will be available through OpenHardware.co.za and other stores for around R5 000 or less.

OpenHardware.co.za is owned by Peter van der Walt, a man who knows a thing or two about 3D printers, having built somewhere in the region of 150 over the last few years. van der Walt is a founding member of South African makers’ collective House4Hack, and two years ago he started the Durban-based OpenHardware.co.za hoping to “bridge the gap between the hobbiest” and retail. OpenHardware.co.za sells low cost engineering parts like OpenBeam kits to reseller partners, and also operates its own direct shopping frontpage.

Through the online store of OpenHardware.co.za, he’s sold over 110 custom-built 3D printers to early adopters and enthusiasts and has supported home-grown designs like the award-winning RepRap Morgan at prices well below those you’ll find in RS Online or Dion Wired both in kit form or fully assembled.

van der Walt’s shop is just one of a handful of places in South Africa where you can find the specialist parts you need to build a RepRap-derivative 3D printer, and is – as far as I know – the sole supplier of pre-built hotends in the country. Without a hotend to melt and extrude plastic, a 3D printer is just a very clever but ultimately useless stationary robot.

The launch of the new printer marks a significant new period in the evolution of OpenHardware.co.za. It’s the first printer the firm has designed totally in-house, but more importantly it’s also the first aimed at general consumers rather than those willing to try and build a 3D printer themselves. It comes pre-assembled, for a start, and requires less maintenance than a normal kit-based printer.

With two retailers – Communica and the hackerspace at the University of Pretoria – already lined up to sell the printer it could also establish OpenHardware.co.za’s long-term viability and create enough capital for van der Walt to expand product lines and employ more staff.

“We set ourselves a goal in 2012 to become ‘the’ organisation in South Africa to promote open source hardware,” says van der Walt, “That means we need to pull up our socks, stop “hacking” and start thinking of things like “sustainability”, “growth” and protecting our

relationships with resellers.”

The other key reason that he wants to sell wholly South African designed printer, says van der Walt, is to be able to take into account local economic conditions. Prices for basic ingredients like nuts and bolts for established designs are starting to rise, pushing costs up above international equivalents.

“Demand started to overtake supply using the RepRap production methods we were using too,” he says, “It became more and more clear that we need to start looking at an alternate production method or we’d need to invest in at least 4 more printers to keep up with the demand in a reasonable lead time.”

Previous and current RepRap kits sold through OpenHardware.co.za – principally the Prusa Mendel-based EcksbotZA and RepRap Morgan – are a lot of fun, but the primary aims for the new printer are that it can be easily and relatively cheaply mass produced and be very reliable.

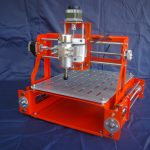

The printer itself is an evolution of a design drawn up by fellow South African hacker Waleed Kahn for an open source CNC milling machine, which is also on sale at OpenHardware.co.za. The project has gone from initial idea to third (and hopefully final) prototype in just three months.

“On March 23rd, I had a long conversation with our Solidworks engineer, Waleed Kahn, to start development of a small, easy to manufacture 3D printer using the same production methodology we used on the OpenCNC-ZA machines, namely sheetmetal,” says van der Walt, “By the week ending April 26th I was in Nelspruit on a project, and had a late afternoon return flight on the Saturday 26th. I had to checkout of the guesthouse early in the morning, which left me with six hours in Nelspruit and nothing else to do but park in the Wimpy at Kruger Mpumalanga, armed with a notebook and Sketchup. By the time I boarded I already sent off the files of the frame design to Waleed for review.”

This may be the only 3D printer ever designed in sight of the Kruger National Park.

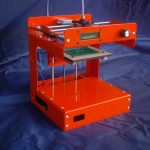

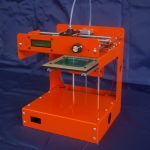

Prototype number three has just arrived at van der Walt’s workshop, fresh with an industrial style powdered finish to the steel body. Unusually, the X and Y-axis for the print head are fixed and rigid at the top of the body, while the print bed itself descends with each layer of the print.

Like fellow House4Hacker Richard van As’ RoboBeast, it’s the rigidity of the frame compared to homebrew models that should keep the printer performing accurately time after time – although van der Walt is aiming for a price tag around a quarter of that of the RoboBeast. The tough design isn’t just about ease of use.

“[Selling 3D printers in] kit form saves on assembly labour but the support load does take its toll,” says van den Walt, “When you work on the low markup we were using one broken controller can eat all the profit on one kit in a minute. Not offering a warranty is the standard open source hardware backup plan – but it should not be like that.”

van der Walt says that he’s planning to have more models to use as demo units by within the next couple of weeks, there’s just one thing left to decide: the new printer doesn’t have a name yet.

“Internally we referred to it as Babybot,” he says, “Because we planned to have a 100x100x100mm print area. Turns out it’s a bit bigger than that after assembly, and we plan to have a 200x200x150mm-capable frame in the coming week or two. So Babybot won’t suffice as a name.”

Want to know what the latest South African 3D printer is going to be called? Watch this space. In the meantime, here’s a video of the OpenCNC machine upon which the new printer is based in action below.

[Images – Peter van der Walt]